For facility managers overseeing agricultural operations, equine centers, or large rural properties, the design and construction of animal housing directly impacts animal welfare, handler safety, and long-term operational costs. While not a traditional piece of logistics equipment, a well-designed horse stall system is a critical infrastructure component for any facility that manages livestock. It combines principles of secure containment, ergonomic access for personnel, and durable material science to create a safe and efficient working environment. This article provides a technical and operational overview of pre-fabricated bamboo stall systems, focusing on their application in professional equine facilities.

The Strategic Role of Animal Housing in Facility Operations

For facilities that combine agriculture with other industrial activities, such as large farms, breeding centers, or rural logistics hubs with associated stables, the efficiency and safety of animal housing directly affect daily workflow. Time spent managing difficult or unsafe stall components translates to lost productivity. Injuries to animals or handlers result in significant operational disruption and cost. Therefore, selecting a stall system based on sound engineering, durable materials, and thoughtful design is a decision that impacts the facility’s bottom line and operational reputation.

Technical Overview and Core Functionality of Modular Stall Systems

System Architecture and Material Composition

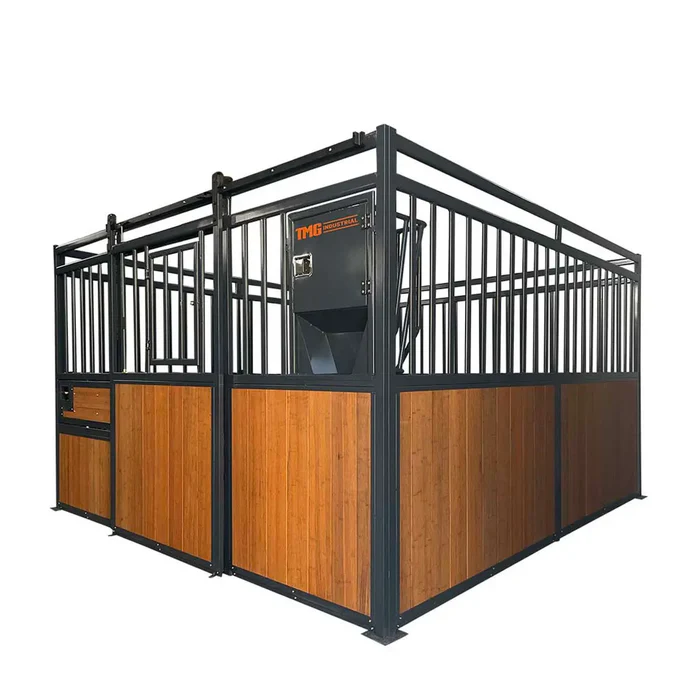

A modern modular stall system is more than a simple enclosure. It is an integrated assembly of panels, doors, and hardware designed for specific functional zones within the stall. A typical kit, such as the 12’ Horse Stall Bamboo Panel system, includes one front panel with an integrated door and feeder/window opening, plus three solid side and rear panels to form a complete 12-foot by 12-foot enclosure. The choice of materials is fundamental to the system’s performance. These units combine a structural galvanized steel frame with infill panels made from heavy-duty bamboo. This hybrid approach leverages the strength and corrosion resistance of the steel framework with the natural durability, aesthetic warmth, and safety characteristics of bamboo.

Integrated Design Features for Functionality

The front panel serves as the primary interface between the handler and the animal. Key integrated features include:

- Vertical Bar Top Section: Allows for ventilation, light, and visual contact for the horse while maintaining secure containment.

- Solid Bamboo Lower Section: Provides a durable, kick-resistant surface that protects the animal and contains bedding.

- Customizable Window/Feeder Opening: A hinged panel that can securely pin to the frame, allowing for the installation of a window or a feeder. This flexibility enables adaptation to different management styles and feeding routines.

- Sliding Door with Double-Gravity Latch: The primary access point. The double-gravity latch is a critical safety feature, designed to self-engage and resist being accidentally opened by the animal, while remaining easy for handlers to operate.

The Critical Importance of Efficiency, Safety, and Productivity in Stable Design

Every interaction with a stall—feeding, cleaning, health checks, handling—represents a point where design either facilitates or hinders work. An efficient stall design reduces the time required for these tasks. Features like a smoothly operating latch and a fold-flat window panel minimize effort and allow handlers to work quickly and confidently. Safety is paramount. A secure latching mechanism prevents escapes that could lead to animal injury or accidents. Smooth, finished surfaces on bamboo panels and protected hardware reduce the risk of cuts and scrapes for both horse and handler. A well-designed stall contributes to a calmer animal, which inherently improves handler safety and productivity. Over the long term, durable materials like powder-coated steel and dense bamboo reduce maintenance downtime and replacement costs, directly contributing to operational productivity.

Technical Foundations and Capability Considerations

Structural Engineering and Material Properties

The technical foundation of the stall lies in the synergy between its steel frame and bamboo infill. The primary frame uses 1-1/4 inch by 2-3/4 inch galvanized steel tubing, with secondary framing of 1-1/4 inch by 2 inch steel. This gauge of steel provides the necessary rigidity to withstand the forces exerted by large animals leaning, kicking, or pushing against the walls. Galvanization and an architectural-grade powder-coated finish with ultraviolet inhibitors provide a multi-layered defense against rust, corrosion, and fading from sun exposure, which is critical for longevity in varying climates.

The bamboo panels, at 3/4 inch thickness, are pre-cut, beveled, and stained. Bamboo is selected for its high tensile strength—comparable to some mild steels on a per-weight basis—and its natural resistance to moisture absorption and insect damage. The beveled edges ensure tight, flush joints between panels, eliminating pinch points and creating a smooth interior surface. The pre-staining provides a uniform, finished appearance and an initial layer of protection.

Safety Engineering in Hardware

The double-gravity latch on the front window/feeder opening is a prime example of safety-focused design. This type of latch uses gravity to keep it in the locked position; unless physically lifted by a handler, it will not disengage. This prevents horses from learning to open the latch. The front sliding door itself operates on a robust roller system, designed for smooth, quiet movement and to prevent jamming. The design allows the window to fold flat against the front of the stall when open, removing a projecting obstacle that handlers could bump into or that could catch on equipment.

Factors Influencing Performance, Safety, and Effectiveness

The long-term performance of any stall system depends on several factors beyond its initial specifications. Installation quality is paramount; the panels must be plumb, level, and securely anchored to a solid, level floor to prevent racking and stress on the frame connections. The facility’s environment plays a role; high humidity or exposure to harsh chemicals during cleaning can challenge even the best finishes, making regular maintenance necessary. Animal behavior is a significant variable; particularly aggressive or anxious horses will place greater demands on the structure. Regular inspection of latches, door rollers, and panel connections for wear, looseness, or damage is essential to identify and correct issues before they lead to a failure or safety incident.

Safety Considerations and Best Practices for Stable Operations

Maintaining a safe environment requires consistent protocols from all personnel.

Essential Safety and Operational Protocols

- Pre-Use Inspection: Before each use, handlers should quickly check the door latch and window latch for positive engagement. Inspect door rollers for smooth operation and ensure the door track is clear of debris.

- Routine Maintenance Checks: On a weekly or monthly basis, depending on use, conduct a thorough inspection. Check all bolts and connections for tightness. Inspect bamboo panels for splinters, cracks, or signs of chewing damage. Lubricate door rollers and latches as recommended by the manufacturer. Check the powder coating for chips or rust spots and address them promptly to prevent corrosion.

- Handler Protocols: Always ensure the door is fully secured before entering the stall. Never attempt to force a jammed door or latch. Keep stall aisles clear of obstructions to allow for safe horse movement. When the window is open, be aware of the potential for a horse to reach out and ensure the area is clear.

- Emergency Planning: Ensure all personnel know how to quickly and safely open stall doors in an emergency. Practice emergency evacuation procedures involving horses.

Equipment Types, Tools, and Associated Components

A complete stall system is just one part of a functional stable. Associated equipment and tools include:

- Stall Flooring: Appropriate footing materials such as mats, bedding (straw, wood shavings, rubber), and proper drainage systems.

- Feeding and Watering Systems: Hay feeders, grain buckets, and automatic waterers that can be integrated with the stall’s feeder opening.

- Ventilation: Barn ventilation systems to ensure air quality and reduce ammonia from urine.

- Maintenance Tools: Basic tools for assembly and maintenance, including socket sets, levels, and lubricants.

- Optional Accessories: Stall guards, screen doors for summer use, and nameplate holders.

Advantages, Limitations, and Practical Application

Strategic Benefits of Bamboo Stall Systems

The primary advantage of a pre-engineered bamboo stall system is the combination of durability, safety, and aesthetic appeal in a package designed for straightforward assembly. The use of bamboo offers a natural, warm appearance that many facility owners prefer over all-metal stalls, while providing excellent strength. The pre-finished components reduce on-site labor compared to building from scratch. The safety-engineered features, like the double-gravity latch, provide peace of mind. The ability to customize the front opening for a feeder or window adds functional flexibility.

Inherent Limitations to Consider

While durable, bamboo, like any wood product, is not indestructible. It can be damaged by persistent chewing or kicking from determined animals, though its density makes it more resistant than many softwoods. The initial cost of a pre-fabricated system may be higher than constructing a stall from dimensional lumber, but this must be weighed against the labor savings and long-term durability. The system is designed for a standard 12-foot by 12-foot stall footprint; customization for non-standard sizes is limited. Installation requires a team and careful attention to leveling and anchoring on a suitably prepared base.

Real-World Facility Application Example

A large boarding and training facility in Kentucky decided to renovate its older, aging barn. The existing stalls, built from rough-cut lumber, were showing significant wear, had protruding nails and splintered edges posing safety risks, and were difficult to keep clean. The facility managers chose to replace them with a complete set of bamboo panel systems. The pre-fabricated nature of the kits allowed for a phased renovation, with new stalls being assembled over a few months with minimal disruption to ongoing boarding operations. Post-renovation, handlers reported that the smooth surfaces were much easier to sanitize, the latches operated reliably, and the horses appeared calmer in the brighter, more uniform environment. The investment not only improved safety and efficiency but also enhanced the facility’s marketability to potential clients seeking high-quality accommodations.

Conclusion: Future Trends and Strategic Integration in Facility Management

The evolution of animal housing systems reflects broader trends in facility management: a focus on durable, low-maintenance materials, safety-engineered design, and efficient installation. Bamboo, as a rapidly renewable resource, also aligns with growing interest in sustainable building practices. We can expect to see continued refinement in hardware design for even smoother operation and security, as well as potential integration of smart sensors for monitoring animal health or stall conditions.

For procurement specialists and facility managers overseeing equine operations, selecting a stall system is a capital investment decision that affects daily workflow, safety, and long-term maintenance budgets. A thorough evaluation of material quality, engineering, and safety features, as exemplified by a comprehensive system, is essential. Proper installation, combined with ongoing staff training and a proactive maintenance schedule, ensures that this investment provides a safe, efficient, and durable home for animals and a productive workspace for handlers for many years.