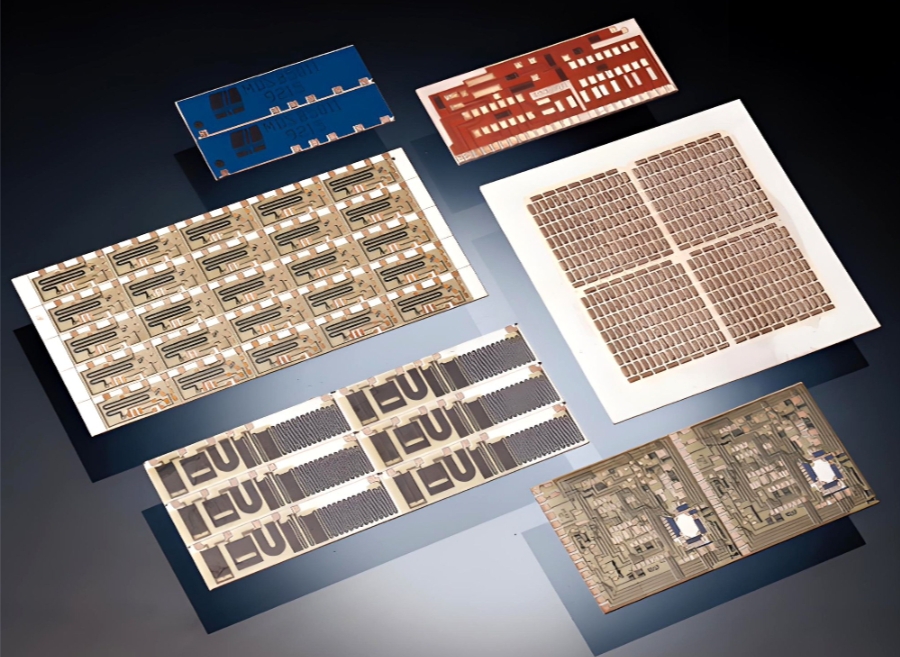

What is a Ceramic PCB?

Ceramic PCBs are made up of ceramic material instead of conventional fibreglass or epoxy. The durability and reliability of ceramic circuit boards are due to the ceramic material properties and also it proves as a great alternative to electronic components, as this material was first used in ceramic capacitors. Ceramic PCB boards require fewer toxic chemicals than traditional PCBs, which is why they are considered environment friendly and sometimes called green PCBs. As this guide proceeds it covers more detailed contents related to ceramic PCBs like materials, advantages, and applications.

The Materials of Ceramic Printed Circuit Boards

A wide range of ceramic materials is available to fabricate ceramic circuit boards, namely Aluminum Oxide (Al2O3), Silicon Carbide (SiC), Aluminum Nitride (AlN), Boron Nitride (BN), and Beryllium Oxide (BeO). Let’s explain the three widely used materials in detail.

1. Aluminum Oxide (Al2O3)

Aluminum is a ceramic material widely used in PCBs. This material is made up of oxygen and aluminum. 95% of aluminum improves the resistivity of this compound with excellent electrical insulation. Aluminum oxide offers dielectric strength and great thermal stability.

2. Aluminum Nitride (AlN)

AlN has a hexagonal crystal structure with a bluish-white colour in its purest form. This non-oxide AlN is a synthetic compound that offers better thermal conductivity, which makes it suitable for high-power applications that generate heat.

3. Silicon Carbide (SiC)

Some properties of the semiconductor material silicon carbide are high chemical resistance, high thermal conductivity coefficient, and low thermal expansion coefficient.

For high-temperature sensors, power modules, and many aircraft electronics, it is suggested to use SiC ceramic printed circuit boards.

4. Beryllium Oxide (BeO)

Beryllium oxide is a crystalline solid inorganic material with a white colour. Not only does it have very good electrical insulating properties, but it is also superior to all nonmetals and metals in terms of thermal conductivity. Just like diamonds, there are covalent bonds between the Beryllium oxide atoms to the other atoms in the compound. This transfers heat through these bonds as vibrations, with little energy being used. Due to its relatively high melting point, excellent electrical resistance, and high heat capacity, it is useful in other areas as well.

The Benefits of Ceramic PCB Boards

Ceramic printed circuit boards offer various advantages due to which they are widely employed in daily applications. The following are some reasons that make them popular in the electronic industry.

1. High Thermal Conductivity

Due to higher thermal expansion constant, ceramic PCB boards are considered proficient in terms of thermal management and heat dissipation. The variation in the values is from 25W/(mK) up to 330W/(mK). It is more than 20 times that of FR-4 PCB. Ceramic is better and can protect a gadget from heat-related damage due to this property.

2. Low Dielectric Loss

Electromagnetic fields lower the dielectric loss of the ceramic material. Free electrons are allowed to flow when a highly conductive material is exposed to charge, and the opposite of this is happening in insulators i-e lower electron flow. Insulators are widely used in industrial applications in which there is lesser dielectric loss at higher voltages.

3. High Mechanical Strength

The mechanical strength and stability of the ceramic make the ceramic printed circuit board have enhanced resistance to mechanical stress, vibration, or shock. Enhanced mechanical performance reliability ensures that electronic devices are not easily compromised by unfavourable and harsh environmental conditions.

4. Excellent Electrical Insulation

Ceramic PCB board also has better electrical insulating properties; thus, it can be used where high voltage or electrical risks are prevailing. Better electrical insulation improves electric circuit functions and safety since there will be no short-circuiting or electrical discharge.

5. Environmental and Chemical Robustness

Ceramic PCB boards are used in acidic or corrosive environments because the PCBs cannot be affected by chemicals or moisture, and they can also withstand very harsh environmental conditions. It is due to the property of ceramic material to sustain and provide resistance to chemical and harsh environmental factors which eventually enhances the reliability and durability of electronic appliances.

6. High-Frequency Applications

Ceramic PCB boards offer various benefits which prove beneficial to use them in high-frequency applications like high thermal conductivity coefficient, and low dielectric constant. These properties are important for maintaining signal integrity at higher frequencies while keeping the signal attenuation lower.

Applications of Ceramic Circuit Boards

As ceramic PCBs offer various benefits over traditional PCBs, they are used in a lot of electronic applications ranging from health to aerospace, some of these are jotted down below.

Due to the various benefits of ceramic circuit boards, almost every electronic appliance has multilayer ceramic PCBs as the backbone. Some major applications are jotted down below ranging from microwave circuits to medical and aerospace applications.

1. Power Electronics

The application of ceramic PCBs in power electronics has an increasing trend, this is because power electronics devices generate more heat than other devices, which need to be dissipated efficiently for more durability and reliability, and ceramic printed circuit boards prove the best fit for such applications as they offer more thermal management with high heat conductivity and higher electrical insulation.

2. Microwave Circuits

An important aspect of microwave application is to maintain signal integrity with minimal signal attenuation. Properties of ceramic materials like low dielectric constant prove beneficial in such scenarios. Components that operate at higher frequencies may generate heat that needs to be dissipated, good thermal management of ceramic substrate PCBs makes them perfect to be employed in such applications.

3. Aerospace Electronics

Aerospace applications require mechanical strength, thermal management, high-frequency communication systems, and reliability. All these needs can be successfully fulfilled by using multilayer PCBs which enhance the efficiency of electronic devices in aerospace operations.

4. Medical and Healthcare

Ceramic materials have no adverse effects on the human body and offer reliability and durability which make them suitable for deployment in medical devices that require accuracy and precision like monitoring systems and diagnostic systems.

Conclusion

In Nutt-shell, there are a lot of benefits besides durability and reliability that ceramic circuit boards offer in electronic applications. Nowadays ceramic substrate PCBs are employed in aerospace, medical monitoring systems, and microwave circuits due to the properties they offer like lower dielectric constant, minimal signal attenuation, high thermal dissipation, improved signal integrity, with improved efficiency. With the advancements in technology, they are expected to play continued roles as enablers of innovation and development in electronics.