Intermodal transport has become a foundation of global trade, allowing cargo to move smoothly across ships, trucks, and railways without unpacking and repacking the goods. This system depends heavily on equipment designed for efficiency and reliability, and one of the most essential pieces of that equipment is the gooseneck container chassis. Although the name may sound technical, this type of chassis plays a straightforward but vital role in keeping the global supply chain moving. As an SEO expert exploring the needs of modern logistics, I want to break down what makes this equipment unique, how it works, and why it has become the preferred choice for intermodal operators worldwide. Understanding these details gives shippers, fleet owners, and logistics professionals a clearer picture of why choosing the right chassis matters more than ever.

Understanding the design of a gooseneck container chassis

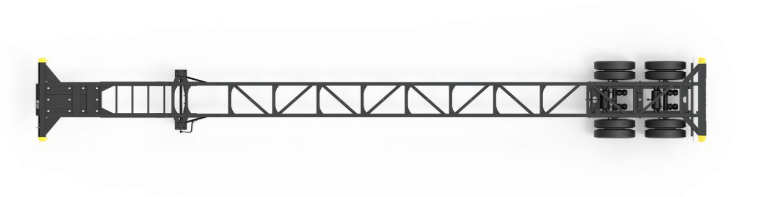

A gooseneck container chassis is a trailer frame engineered specifically to carry ISO shipping containers. Unlike a standard flatbed trailer, it has a recessed or lowered front section called the gooseneck. This indentation allows the container to sit lower in the front so the overall loaded height remains within legal limits. The recessed shape is not just for appearance. It is a technical solution developed to solve the challenge of transporting tall container loads safely and legally on highways that often have strict height regulations.

The gooseneck shape also aligns with the structure of most 40 foot and 45 foot ISO containers. These containers have a tunnel beneath the front section, and the gooseneck design fits precisely into that space. This perfect fit keeps the container locked in a stable position and distributes weight more efficiently. While many flatbed trailers can technically transport containers, they lack the optimized geometry that the specialized chassis provides. As a result, the gooseneck container chassis has become the industry standard for long distance highway container transport.

How the gooseneck design improves safety and stability

Safety is one of the key reasons this chassis type is so widely used. The lower load position created by the gooseneck reduces the center of gravity. A lower center of gravity improves stability during turns, braking, and sudden maneuvers. When a container sits too high on a flatbed, the risk of tipping increases, especially in windy conditions or on uneven roads. The gooseneck design counters this risk by keeping the load closer to the axles and closer to the ground.

Weight distribution is another major factor. Containers are often extremely heavy, and improper distribution can stress axles and compromise handling. The design of a gooseneck container chassis ensures that weight is spread evenly across the trailer frame. This contributes to smoother travel and better braking performance. For fleets operating large numbers of trailers, reduced strain on axles and suspension systems also translates to fewer maintenance issues and longer service life.

Why the gooseneck container chassis is ideal for intermodal transport

Intermodal logistics demands speed, precision, and compatibility. Since cargo moves between ships, trucks, and trains, the equipment used must allow fast and secure transfers. The gooseneck container chassis supports all of these needs.

One of its biggest strengths is compatibility with spreaders and lifting equipment used in ports and rail yards. Cranes can latch onto the top corners of ISO containers and place them directly onto the chassis with no adjustments needed. The container locks into place using twist locks mounted on the chassis. These twist locks hold the container securely during transport and can be engaged or disengaged quickly by a driver or yard operator.

The design also helps with time efficiency. Ports and terminals manage thousands of containers daily, and delays can be costly. The gooseneck chassis is engineered for fast loading and unloading because the dimensions match ISO standards precisely. This reduces the chance of misalignment and speeds up operations, which is crucial in intermodal environments where every minute counts.

Materials and construction features that enhance durability

A Gooseneck Container Trailer must withstand rough environments, heavy loads, and constant use. Manufacturers typically use high tensile steel to build the chassis frame. This type of steel offers a superior strength to weight ratio, meaning the chassis remains strong without being excessively heavy. A lighter chassis can carry more payload without violating weight limits, which is important for operators trying to maximize efficiency.

Modern production methods also improve durability. Many advanced manufacturers use robotic welding for clean, consistent welds that reduce weak points in the frame. Laser cutting technology ensures that each component fits precisely, improving overall structural integrity. Coating processes such as powder coating or specialized corrosion protection treatments extend the lifespan of the chassis. These coatings protect the metal from saltwater exposure, road chemicals, and weather damage, all of which are common in port and highway environments.

How a gooseneck container chassis differs from other chassis types

Intermodal fleets use several chassis configurations depending on their needs. Some of the most common types include:

- Standard 40 foot chassis

- 20 foot tri axle chassis

- Extendable chassis

- Gooseneck chassis for 40 foot and 45 foot containers

- Combo chassis that adjust to multiple sizes

While each type has its purpose, the gooseneck container chassis stands out because of its specialized design. It offers advantages in load stability, height clearance, and container compatibility that other chassis types cannot match. For operators who frequently move 40 foot or 45 foot containers, the gooseneck becomes the most practical and cost effective option.

Benefits of using a Gooseneck Container Trailer in large fleets

Large trucking and logistics companies rely on repetition and consistency. When a fleet uses Gooseneck Container Trailer units, operations become more standardized. Drivers know exactly how containers will fit, how weight will distribute across axles, and how the equipment behaves on the road. This consistency improves training, safety, and operational efficiency.

From an economic perspective, the ability to carry heavier payloads within legal height limits increases profitability. Time savings at ports and terminals also reduce overall operating costs. Since these chassis are designed for heavy, continuous use, they often offer longer life cycles, reducing the need for frequent replacements.

Everyday applications in today’s logistics industry

Although most people associate container chassis with long haul trucking, the reality is that these trailers play a vital role in multiple sectors of the supply chain. They are used in:

- Port drayage, where containers are moved short distances between docks and storage yards

- Rail yard transfers, supporting container movement between trains and trucks

- Distribution centers that handle imported cargo

- Manufacturing plants receiving raw materials in containers

- Export operations moving finished goods to ports

Because of its versatility and efficiency, the gooseneck chassis supports nearly every part of international commerce. Any company using ISO containers benefits from this equipment in some form.

What to consider when selecting a container chassis

Choosing the right Container Chassis depends on several factors. Fleet managers should consider:

- Load capacity requirements

- Container sizes commonly transported

- Road and terrain conditions

- Frequency of port or rail yard operations

- Maintenance capabilities

- Manufacturing quality and material strength

Operators should also look at regulatory compliance. Many regions enforce strict rules regarding axle weights, trailer height, and container securement. A well designed chassis helps ensure compliance and reduces the risk of fines or delays.

Final thoughts: Why the gooseneck chassis remains essential

The gooseneck container chassis is more than just a transport frame. It is a specialized tool that supports the entire intermodal system. Its design improves safety, stability, and efficiency while helping operators meet legal height restrictions and weight distribution requirements. As global trade continues to grow, industries need reliable equipment that can keep up with increasing demand. This chassis type delivers exactly that.

For businesses that depend on container transport, understanding how this equipment works can influence smarter purchasing decisions and better long term fleet strategies. Whether you are new to intermodal logistics or expanding an existing operation, the gooseneck chassis remains one of the most valuable assets in modern transportation.