The printing and customization industry is evolving faster than ever. With customers demanding higher-quality prints and shorter turnaround times, print shops across the U.S. are upgrading their equipment to stay competitive. One of the clearest trends is the rapid adoption of pneumatic heat press machines—a major upgrade from traditional manual presses.

Unlike manual systems that rely on operator strength, pneumatic heat presses use controlled air pressure to deliver consistent results. For print shops running DTF, DTG, vinyl, or sublimation workflows, this upgrade has become essential.

Precision That Manual Presses Can’t Provide

The final pressing stage can make or break a product. Even the best printers can’t compensate for a press that delivers uneven pressure or fluctuating heat. Manual presses often struggle with:

- pressure variation

- operator fatigue

- inconsistent results on thick garments

- difficulty handling irregular items

A pneumatic heat press eliminates these issues by delivering stable, automatic pressure across every press cycle. Shops benefit from

- stronger adhesion

- sharper colors

- fewer misprints

- lower waste and rework

For growing print shops, this level of precision directly impacts customer satisfaction and repeat business.

Why Many Shops Are Choosing Pneumatic Dual Heat Press Systems

In today’s market, speed is a competitive advantage. Shops that can process more orders efficiently win more clients—especially in print-on-demand and corporate apparel sectors.

A pneumatic dual heat press is one of the fastest ways to boost throughput without adding staff.

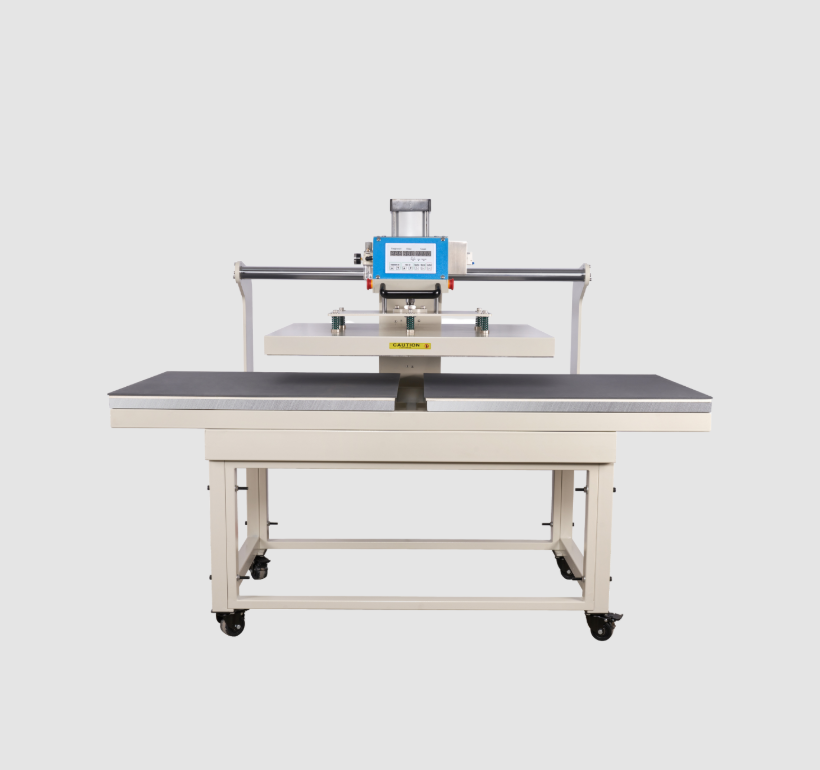

16×24 Pneumatic Dual-platen Heat Press Built-in 5 Gallon Air Compressor

Because it features two working platens, operators can load one side while the other is pressing. This continuous rotation results in:

- 30–60% higher productivity

- shorter turnaround times

- smoother workflow for small teams

- reduced physical effort

For shops moving from hobby-level to production-level volumes, a dual-station pneumatic press is often the smartest investment.

Large-Format Pneumatic Presses for Expanding Product Lines

28″x36″ Large Format Pneumatic Dual Platen Heat Press

Customization is no longer limited to T-shirts. Consumers and businesses now want personalized:

- blankets

- pillows

- banners

- tablecloths

- wide-format apparel

- soft signage

To meet this growing demand, more shops are adopting the pneumatic large heat press, which supports oversized materials and thick substrates. It delivers even pressure across large surfaces—something manual models simply can’t guarantee.

Large-format pneumatic presses enable shops to expand into high-margin markets, opening new revenue streams beyond apparel.

Better Automation for Modern Production Workflows

The printing industry is rapidly shifting toward automation. Shops are standardizing their processes, integrating digital tools, and training staff faster than ever. Pneumatic systems fit naturally into this transformation.

Many pneumatic presses now offer:

- digital pressure settings

- automatic open features

- consistent heat regulation

- safety sensors

- programmable presets

These features reduce operator error, minimize fatigue, and ensure consistent results—even with inexperienced staff.

As a result, pneumatic presses help shops scale smoothly during busy seasons or rapid business growth.

A Practical Way to Overcome the Skills Gap

Finding skilled press operators is increasingly difficult. New employees may struggle with manual pressure, leading to mistakes and wasted materials.

Pneumatic heat presses simplify the job dramatically.

Since pressure is controlled automatically, new operators can learn quickly and produce reliable results from day one. Shops benefit from:

- reduced training time

- lower labor costs

- fewer defects

- less physical strain on workers

For high-volume environments, this consistency is invaluable.

Where Print Shops Are Buying Pneumatic Heat Press Machines

With demand for pneumatic systems rising, businesses are choosing manufacturers that offer reliability, strong pressure output, and durable construction. One supplier many U.S. print shops choose is Kilo Heat Press, known for:

- pneumatic heat press machines for everyday production

- pneumatic dual heat press systems for continuous workflows

- pneumatic large heat press units for oversized sublimation

Their equipment is designed to support both small studios and industrial-scale operations.

Learn more at: http://kiloheatpress.com/

Final Thoughts: Pneumatic Heat Presses Are Becoming the New Industry Standard

The growing demand for personalization, faster delivery, and professional-quality results has pushed print shops to upgrade their equipment. Pneumatic heat presses offer:

- consistent pressure

- higher productivity

- reduced labor requirements

- better safety

- long-term durability

Whether you’re running a small custom shop or scaling a full production line, pneumatic heat press, pneumatic dual heat press, and pneumatic large heat press systems provide the reliability and performance needed to stay competitive in today’s fast-moving market.

As customization continues to rise, pneumatic heat press technology is quickly becoming the new standard for modern print shops.